Introduction

In today’s business environment, the pressure isn’t just to work harder—it’s to work smarter. But what does that actually mean in practice?

It means systematically eliminating the “waste” from your workflows: the redundant tasks, the unnecessary handoffs, and the time spent on work that adds no real value to your customer. This is the core promise of lean project management—a framework designed to make your team more efficient, responsive, and relentlessly focused on value.

This guide is a practical playbook, not just a theoretical one. The fundamental question of “what is project management” is evolving, and after more than a decade of managing complex projects, I’ve seen firsthand how these principles turn busy teams into highly effective ones. We will cut through the jargon, clarify the crucial difference between Lean and Agile, and give you a framework you can start using today.

It means systematically eliminating the “waste” from your workflows: the redundant tasks, the unnecessary handoffs, and the time spent on work that adds no real value to your customer. This is the core promise of lean project management—a framework designed to make your team more efficient, responsive, and relentlessly focused on value.

This guide is a practical playbook, not just a theoretical one. The fundamental question of “what is project management” is evolving, and after more than a decade of managing complex projects, I’ve seen firsthand how these principles turn busy teams into highly effective ones. We will cut through the jargon, clarify the crucial difference between Lean and Agile, and give you a framework you can start using today.

Key Takeaways for the Busy Professional

- The Definition: Lean project management is a methodology focused on maximizing customer value by systematically identifying and eliminating waste from your processes.

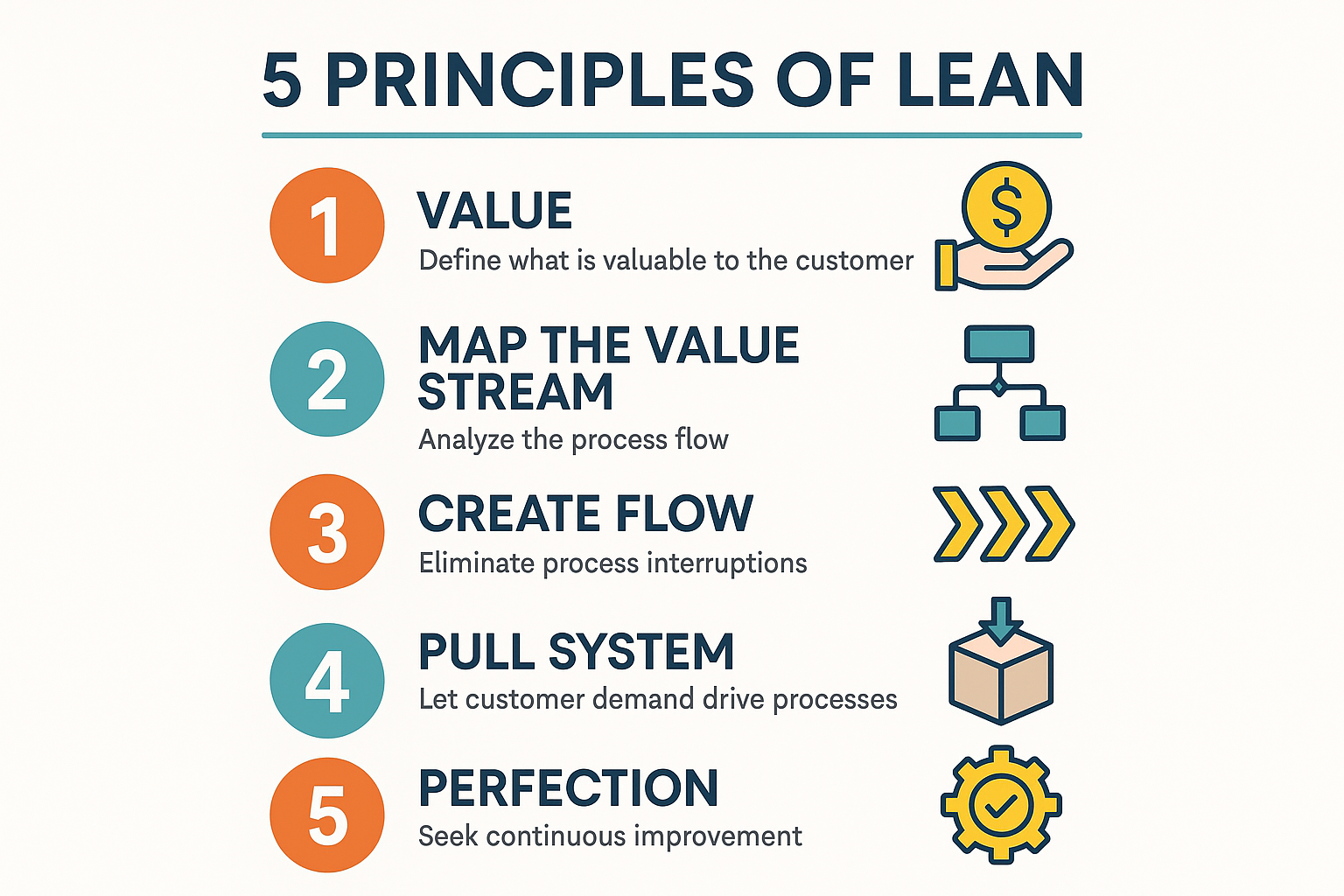

- The 5 Principles: The entire methodology is built on 5 core principles: Identify Value, Map the Value Stream, Create Flow, Establish a Pull System, and Pursue Perfection.

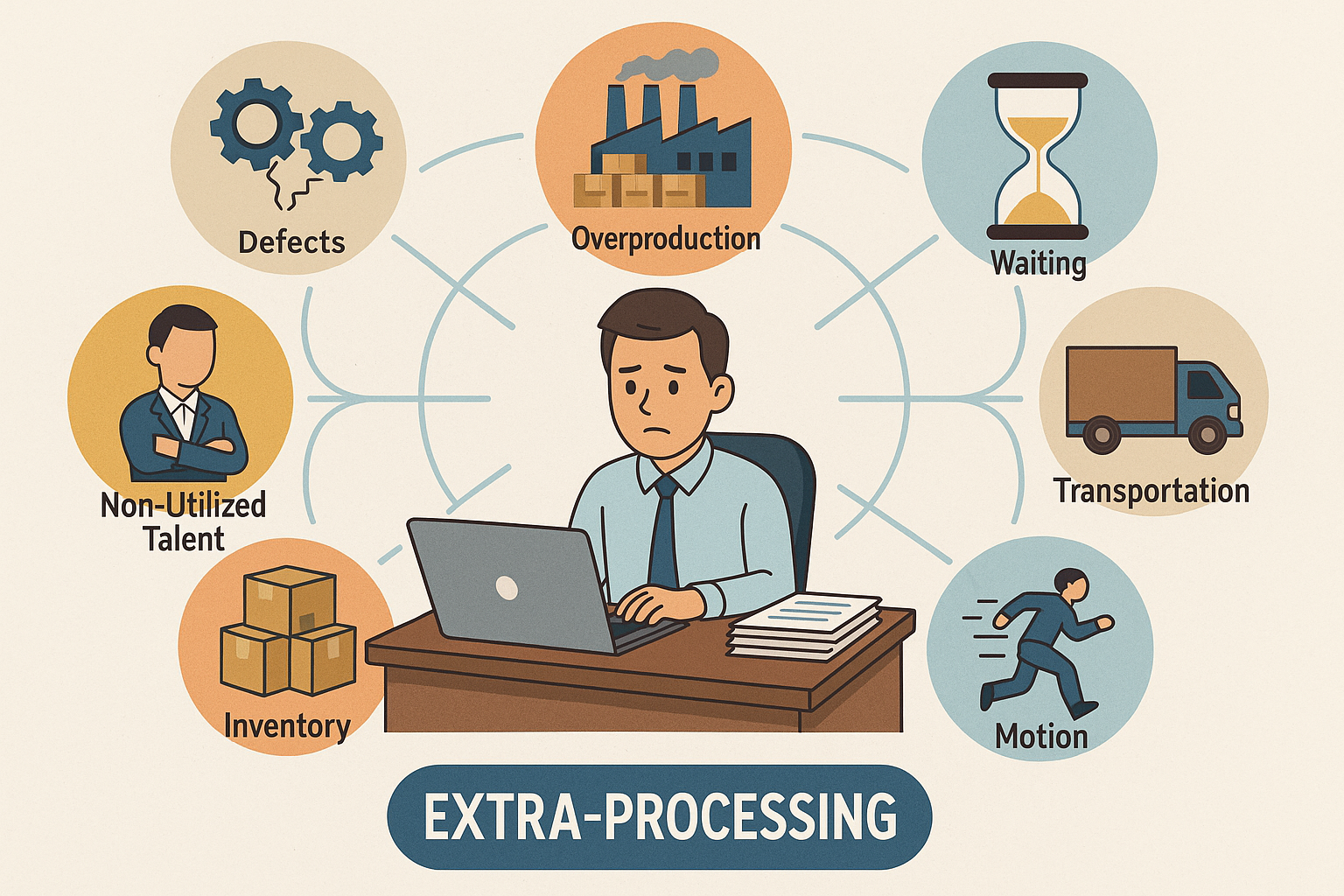

- The 8 Wastes: The practical goal is to identify and remove the “8 Wastes of Lean” from your workflow, many of which are hiding in plain sight in modern offices.

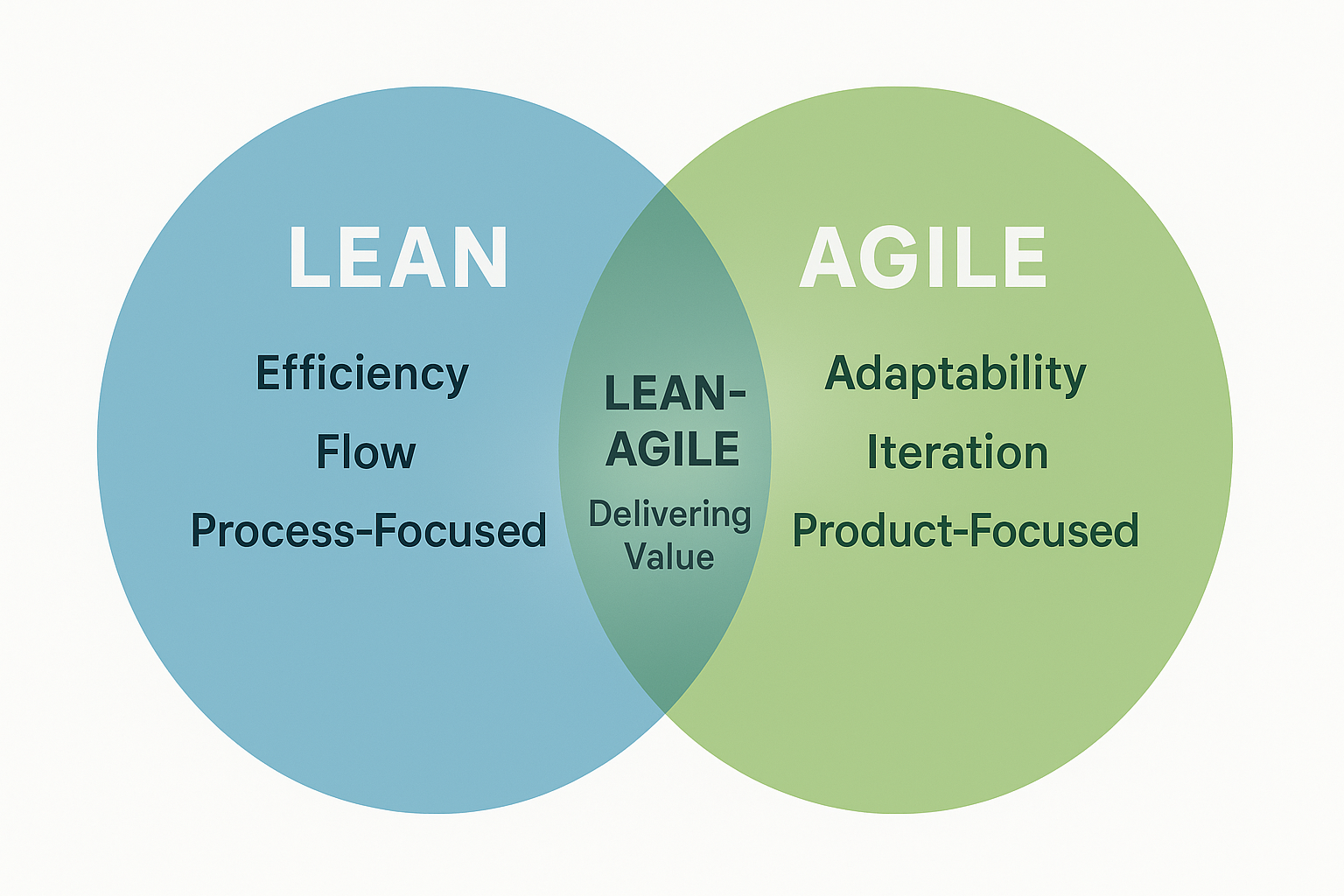

- Lean vs. Agile: Lean focuses on efficiency and waste reduction (building the thing right), while Agile focuses on adapting to change through iteration (building the right thing). They are complementary, not the same.

What is Lean Project Management? A Deeper Definition for Professionals

Let’s get straight to it. Lean project management is the practice of applying the principles of Lean manufacturing—famously pioneered by Toyota—to the world of knowledge work. The single, unifying goal of the lean project management methodology is to maximize customer value while minimizing waste.

It all started with the Toyota Production System, where engineers identified three core types of inefficiency, known as the “3M”:

It all started with the Toyota Production System, where engineers identified three core types of inefficiency, known as the “3M”:

- Muda (Waste): Any activity that consumes resources but adds no real value to the end customer.

- Muri (Overburden): Forcing your team or your systems to work beyond their reasonable capacity, leading to burnout and poor quality.

- Mura (Unevenness): A workflow that operates in a “feast or famine” cycle, with periods of high pressure followed by periods of idle waiting.

Real-World Example: The 3M’s in a Marketing Team

- Muda (Waste): A designer spends 10 hours creating a set of ad graphics that are never used because the campaign’s direction changed.

- Muri (Overburden): The lead copywriter is assigned as the sole writer for three different major product launches in the same week, leading to burnout and a decline in quality.

- Mura (Unevenness): The team experiences a “feast or famine” cycle, with frantic, 80-hour work weeks at the end of every quarter followed by two weeks of little to no work.

The 5 Core Principles of the Lean Project Management Methodology

The entire Lean philosophy can be broken down into five actionable principles. I’ve used these to guide my teams for years, and they are the foundation of any successful lean project management implementation.

1. Identify Value (From the Customer’s Perspective)

This is the most important first step. “Value” is anything the customer is actually willing to pay for. Everything else is, in some form, waste. Your team must have a crystal-clear, shared understanding of what value means for this specific project.According to the Project Management Institute (PMI), high-performing organizations successfully meet their original business goals 82% of the time, compared to only 37% for low-performers, highlighting the power of focusing on value.

Expert Take: “New project managers often mistake the project scope for ‘value.’ A senior PM understands that value is only what the customer would willingly pay for. If you’re building a feature that solves a problem the customer doesn’t care about, it doesn’t matter how efficiently you build it—it’s still waste.”

2. Map the Value Stream (Visualizing Your Workflow)

The “value stream” is every single step required to take a project from concept to delivery. You need to map this entire process out visually. This isn’t just about listing tasks; it’s about seeing how they connect and flow. The goal here is to create a transparent, honest picture of your current process, including any inefficiencies, so you can identify where the waste is hiding.3. Create Flow (Eliminating Bottlenecks)

Once you’ve mapped your value stream, you’ll inevitably find areas where work gets stuck. Creating “flow” means relentlessly removing these blockers so that work can move smoothly through the process without long periods of waiting. A smooth, predictable flow is the sign of a healthy lean project management process.4. Establish a Pull System (Working On-Demand)

A “push” system is when you do work and then push it onto the next person, regardless of whether they’re ready. A “pull” system, a cornerstone of Lean, means the next downstream step signals when it has the capacity to “pull” a new task. This prevents overburdening team members, a common challenge when you need to manage multiple projects with a shared resource pool, and avoids creating wasteful queues of unfinished work.5. Pursue Perfection (Continuous Improvement)

Lean is not a one-time project; it’s a commitment to a culture of continuous improvement, often called “Kaizen.” It means your team regularly reflects on its process and asks, “How can we be a little bit better tomorrow than we were today?” This pursuit is the engine that drives long-term success in lean project management.Identifying the 8 Wastes in Your Lean Project Management Process

In Lean, “waste” (Muda) is anything that adds no value to the customer. The adoption of Agile and Lean principles in non-IT departments has more than doubled, with 71% of marketing teams now using these methodologies, making it crucial to understand waste in a modern business context. Learning to see them is a project manager’s superpower.

- Defects: Work that is inaccurate or incomplete, forcing you to do it over.

- Modern Example: A marketing campaign with a broken link, requiring an urgent, last-minute correction.

- Overproduction: Creating more than is immediately needed.

- Modern Example: Writing 10 blog posts before the product messaging is finalized, risking rewrites.

- Waiting: Time spent waiting for the previous step in a process to be completed.

- Modern Example: A development team sitting idle, waiting for a design to be approved.

- Non-Utilized Talent: Underusing your team’s skills and creativity. A Gallup study found that companies with highly engaged employees (who feel their talents are well-utilized) are 23% more profitable, turning this waste into a direct financial metric.

- Modern Example: I once worked on a project where our most skilled UX designer was stuck doing basic data entry. That’s a massive waste of talent and a significant drain on morale. The lean project methodology teaches you to see and eliminate that.

- Transportation: Unnecessary handoffs of work between teams or systems.

- Modern Example: A document that has to be emailed for approval, then uploaded to a different system, when a collaborative tool could do the job in seconds.

- Inventory: An excess of work-in-progress (WIP).

- Modern Example: A product backlog with 500 unprioritized ideas, creating noise and making it impossible to focus.

- Motion: The effort (like switching between apps) that doesn’t contribute to the work itself.

- Modern Example: A team member having to switch between five applications to find the information needed for one task.

- Extra-Processing: Doing more work than is necessary to deliver value.

- Modern Example: Spending 20 hours on a pixel-perfect internal presentation when a simple slide deck would have sufficed.

Lean vs. Agile Project Management: Understanding the Crucial Difference

Here’s where many professionals get tripped up. Lean and Agile are not the same. They are two powerful, complementary philosophies that work best together.

“After years of practice, here’s the simplest way I can explain it: Agile helps you build the right thing. Lean helps you build the thing right. A successful team needs both philosophies to thrive.”

Where Lean Shines: Efficiency and Process Optimization

Lean’s primary focus is on the process. It asks, “How can we deliver value to the customer in the most efficient way possible?” Its goal is to create a perfect, waste-free production line. This is the heart of the lean project management methodology.Where Agile Shines: Adaptability and Iteration

Agile’s primary focus is on the product. It asks, “Are we building the right thing?” It uses short, iterative cycles (sprints) to get customer feedback early and often, allowing the team to adapt to changing requirements.How Lean and Agile Work Together (Lean Agile Project Management)

A team can use Lean principles to make their Agile process more efficient. For example, they might use a Kanban board (a Lean tool) to visualize their sprint backlog and set a WIP limit (a Lean technique) to ensure they don’t get overburdened during their sprint (an Agile event). This combined approach is often called lean agile project management.“After years of practice, here’s the simplest way I can explain it: Agile helps you build the right thing. Lean helps you build the thing right. A successful team needs both philosophies to thrive.”

Core Techniques for Your Lean Project Management Toolkit

You don’t need to be a Lean guru to start seeing benefits. Here are a few core techniques you can introduce to your team right away.

- Kanban Boards: The Visual Foundation of Lean

A Kanban board is the simplest way to visualize your workflow. It’s no surprise that 77% of project managers use Kanban boards to visualize their team’s workflow and manage tasks. At a minimum, create three columns: “To Do,” “Doing,” and “Done.” This immediately makes your work visible. - Value Stream Mapping: Your Blueprint for Improvement

This is the exercise of physically drawing out every single step in your current process. It is a powerful team activity that forces everyone to confront the reality of how work gets done, revealing hidden delays. - The 5 Whys: A Simple Technique for Root Cause Analysis

When something goes wrong, don’t just fix the symptom. Ask “Why?” five times to get to the root cause. It’s an effective way to find the underlying process issue. - Kaizen: The Philosophy of Continuous, Incremental Improvement

This is less of a tool and more of a cultural commitment. It’s the idea of holding a regular team meeting to ask, “What is one small, incremental thing we can improve in our process next week?” This is a foundational element of successful lean project management.

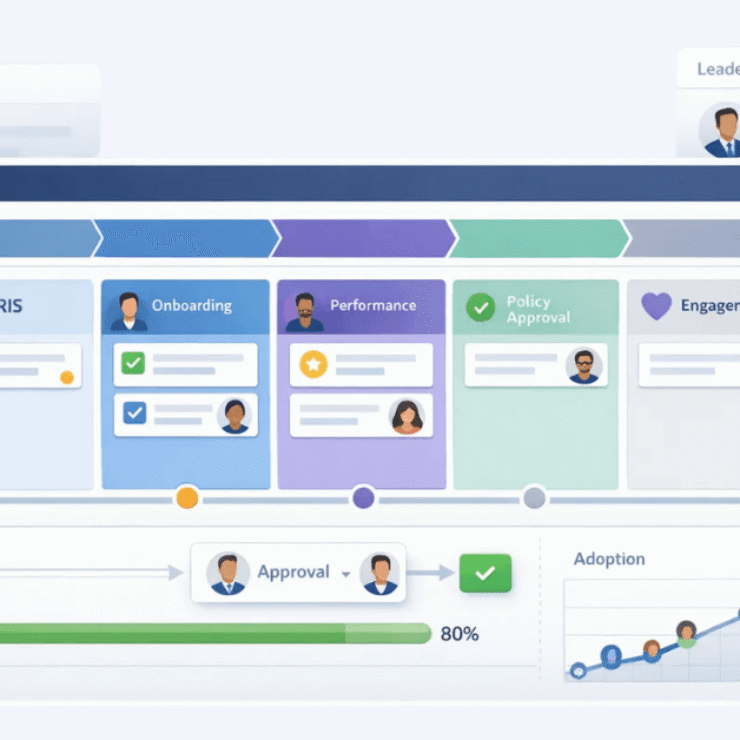

How to Implement Lean Project Management: A 5-Step Guide

Ready to get started? Here’s a practical, 5-step guide to begin your team’s Lean journey.

- Step 1: Start with a Single, Visible Process

Don’t try to change your entire organization at once. Pick a challenging but highly visible process—like your marketing content approval workflow—and get a clear win there first. - Step 2: Assemble the Team and Map the Current Value Stream

Get everyone who touches that process in a room. Map out every single step on a whiteboard. - Step 3: Identify and Prioritize the Waste

Using the 8 Wastes as your guide, have the team circle every step in the process that is waste. - Step 4: Design the “Future State” and Implement Changes

As a team, design a new, leaner workflow. This new workflow becomes your new project plan for how this process will operate. Commit to trying this new process for a set period. - Step 5: Measure, Review, and Foster a Culture of Kaizen

At the end of your trial period, review the results. This is the beginning of your journey toward continuous improvement.

The Best Tools for Lean IT & Business Project Management

Lean is a mindset, but the right tools can help you put it into practice. The best tools for lean project management are visual, flexible, and help you see your workflow clearly.

- For Visual Workflow (Kanban): The Kanban board is the heart of Lean. Trello is famous for its simplicity. Asana and Karya Keeper offer more robust board features that can be customized to your specific workflow stages.

- For Value Stream Mapping: For mapping your process, digital whiteboard tools like Miro or FigJam are invaluable for remote and hybrid teams.

- For Enterprise Lean: Powerful platforms for lean IT project management like Jira can be configured for Lean workflows, but they often require more technical setup.

Conclusion: Embracing the Lean Mindset

As you can see, Lean is far more than a set of tools. It’s a profound shift in how you and your team see your work. It’s about building a culture that is relentlessly focused on delivering value and has the discipline to identify and eliminate everything that gets in the way. It’s not about cutting costs; it’s about becoming more effective.

The journey to lean project management is one of continuous improvement. By taking the first small steps to identify value and eliminate waste, you are on the path to building a more successful team.

The journey to lean project management is one of continuous improvement. By taking the first small steps to identify value and eliminate waste, you are on the path to building a more successful team.

FAQs

What is lean project management in simple terms?

It’s a method for managing projects that focuses on delivering maximum value to the customer by systematically identifying and eliminating waste from your workflow.

What are the 5 principles of Lean?

The five core principles are: 1) Identify Value, 2) Map the Value Stream, 3) Create Flow, 4) Establish a Pull System, and 5) Pursue Perfection (Continuous Improvement).

What is the main difference between Lean and Agile?

Lean focuses on maximizing efficiency and eliminating waste in the process (building the thing right). Agile focuses on adapting to customer feedback through short cycles (building the right thing). They are complementary.

What is an example of a Lean project?

A Lean project could be a marketing team using a Kanban board to manage their content creation process, with a focus on reducing the “wait time” for approvals to deliver content faster.

What is the primary goal of lean project management?

The primary goal of the lean project methodology is to maximize customer value by minimizing waste.