Introduction

If you’ve ever looked at your team’s calendar and thought, “Everyone looks busy—so why are we still missing deadlines?” You’re not alone.

In my 15+ years working with delivery, operations, and cross-functional teams, I’ve seen this pattern repeat across industries. Projects don’t slip because people aren’t working hard. They slip because we confuse activity with capacity.

Capacity planning helps you step back and answer a much more important question:

Can we realistically take this work on and still deliver it well—without burning people out?

This guide explains capacity planning in plain English, shows you how to apply the right strategy, and gives you practical ways to start—without turning it into a heavyweight planning exercise.

What Is Capacity Planning?

Capacity planning is the process of ensuring you have the right amount of capacity available to meet demand at the right time.

In theory, that sounds straightforward. In practice, it’s where many organizations struggle.

Recent research shows that just 33% of organizations feel they use data effectively for capacity planning, and a similarly small share feel confident deciding which capacity data to use or communicating it across teams — a key reason many capacity plans fail to deliver reliable forecasts.

Capacity can include:

- People and their time

- Skills and expertise

- Tools, systems, or infrastructure

- Budget or operational limits

Demand is everything competing for that capacity—projects, tickets, support work, production orders, or new initiatives.

Capacity planning bridges the gap between what needs to be done and what can realistically be done.

It’s closely related to forecasting, but it’s not the same thing. Forecasting predicts demand. Capacity planning checks whether you can absorb that demand without compromising delivery.

Actionable advice: Before committing to new work, ask one question: If nothing else changed, what would break first? That answer usually reveals your real constraint.

Why Capacity Planning Matters

Capacity planning isn’t about squeezing more work out of people. Done well, it helps you:

Prevent missed deadlines without burnout

Teams operating near their limits for too long eventually pay the price—first in quality, then in morale.

Improve delivery predictability

Leaders don’t need perfect estimates. They need reliable commitments.

Make hiring and outsourcing decisions earlier

Spotting a capacity gap early gives you options. Spotting it late gives you fire drills.

Protect customer and SLA commitments

This is especially critical for IT, operations, and support-heavy teams.

Actionable advice: If delivery dates keep slipping even though effort remains high, your problem is likely capacity mismatch, not lack of discipline.

Key Capacity Planning Terms (Without the Jargon)

A few simple definitions make everything else easier:

- Demand: All incoming work requiring effort

- Capacity: What your team can realistically handle

- Availability: Calendar time (not the same as capacity)

- Utilization: Percentage of capacity in use

- Effective capacity: Capacity after meetings, support, and interruptions

- Focus factor: The reality that 40 hours rarely equals 40 hours of output

Actionable advice: If your plan assumes people are productive 100% of the time, the plan is already flawed.

Moreover, many organizations still limit capacity planning to basic headcount forecasts — with 66% of HR leaders reporting they do not yet extend planning to skills or workload alignment — underscoring how maturity in capacity planning remains a challenge.

The 3 Capacity Planning Strategies (And When to Use Each)

Most organizations use these strategies—often without realizing it.

Lead Strategy: Build Capacity Before Demand Hits

You add people or resources ahead of anticipated demand.

Best for

- Seasonal or predictable spikes

- Long hiring lead times

- High cost of delivery delays

Tradeoff: Short-term idle or bench cost.

Lag Strategy: Add Capacity After Demand Is Proven

You wait until demand is confirmed before scaling.

Best for

- Stable, predictable demand

- Work with low urgency or penalties

Tradeoff: Overtime, stress, and delivery risk.

Match Strategy: Scale Gradually

You increase capacity in smaller, incremental steps.

Best for

- Moderate demand volatility

- Agile or iterative delivery environments

Tradeoff: Requires frequent monitoring and adjustment.

Experience-based insight: If hiring lead time is longer than the cost of delay you’re trying to avoid, a pure lag strategy will almost always fail.

This aligns with widely accepted capacity strategy principles, where demand volatility and response time play a key role in choosing the right approach.

Actionable advice: Don’t default to lag strategy just because it feels “safer.” It often shifts risk downstream.

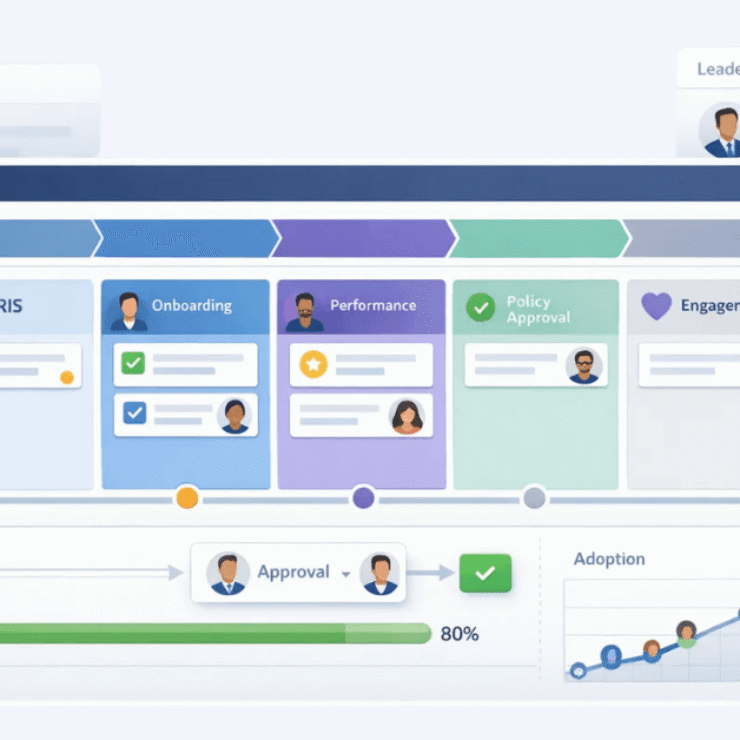

A Practical Capacity Planning Process (Step by Step)

You don’t need complex tools. You need consistency.

Step 1: List All Demand

Include projects, enhancements, support work, meetings—everything.

Tip: Maintain one visible backlog. Side lists hide overload.

Step 2: Define the Planning Horizon

- 2–4 weeks → operational

- 1–3 months → tactical

- 6–12 months → strategic

Step 3: Measure Real Capacity

Account for leave, meetings, on-call work, and recurring overhead.

Step 4: Convert Work into Capacity Units

Use what fits your team:

- Hours

- Story points

- Standard time per unit

Step 5: Identify Gaps

Where demand exceeds capacity—by time or skill.

Step 6: Choose Actions

Reprioritize, shift timelines, add resources, reduce work-in-progress, or automate.

Step 7: Review Regularly

- Weekly: overload check

- Monthly: capacity review

- Quarterly: scenario planning

Actionable advice: Capacity planning works best as a rhythm, not a one-time exercise.

Industry research shows that 77% of high-performing projects use project management software, highlighting a strong correlation between structured planning practices and better project outcomes.

While this data refers broadly to project management software, it reinforces an important pattern: teams that rely on structured planning systems tend to deliver more consistently. Capacity planning plays a critical role within this structure by ensuring commitments are based on realistic availability, not assumptions.

The Simple Math You Actually Need

Effective Capacity (People Teams)

Effective Capacity = Available Hours × Focus Factor – Planned Overhead

Focus factor typically ranges between 60–80%, reflecting meetings, interruptions, and task switching.

Utilization: Why 100% Is a Trap

Across teams I’ve coached, once planned utilization crossed 85–90%, delivery predictability dropped—even though output looked higher on paper.

This observation aligns with established project and operations management guidance, which cautions against planning teams at near-full utilization because it increases context switching, delays, and quality risk.

Actionable advice: Plan for flow, not maximum utilization.

Buffers Are Not Waste

- Project teams: 10–15% buffer

- Support-heavy teams: 20–30% buffer

These buffer ranges are commonly recommended in capacity planning and IT service management practices to absorb variability without overloading teams.

Actionable advice: Buffers are insurance—not inefficiency.

Capacity Planning by Context

Project Teams and Agencies

- Separate billable and non-billable capacity

- Plan for ramp-up and ramp-down periods

Product and Engineering

- Reserve capacity for tech debt and unplanned work

- Avoid planning sprints at full velocity

IT and Infrastructure

- Combine demand forecasting with capacity management

- Monitor incident and support load closely

Operations and Manufacturing

- Apply lead, lag, and match strategies to equipment, shifts, and inventory

Common Capacity Planning Mistakes (And How to Fix Them)

- Treating calendars as capacity

- Ignoring skill mismatches

- Stacking new work on top of support load

- Optimizing for utilization instead of predictability

- Never revisiting assumptions

Experience reflection: Early in my career, I treated capacity planning as a spreadsheet exercise. It took several painful delivery misses to learn that conversations—not formulas—surface real constraints.

Actionable advice: Always validate the plan with the people doing the work.

Best Practices to Apply the Right Strategy

- Start with one team and one planning horizon

- Make tradeoffs visible to stakeholders

- Add a capacity check to work intake

- Run simple “what if” scenarios

- Review and adjust assumptions regularly

Final Thought

Capacity planning doesn’t need a big rollout.

Pick one team. One planning window. One honest conversation.

That alone is often enough to uncover where delivery is breaking—and how to fix it before the next deadline slips.

FAQs

It ensures project commitments are based on real, available capacity—not optimistic assumptions.

Lead, lag, and match—each suited to different demand patterns and risk levels.

Resource planning assigns work. Capacity planning verifies whether that assignment is realistic.

Weekly checks, monthly reviews, and quarterly scenario planning work well for most teams.